濾袋材質介紹:

▲ POLYESTER(PE) : 最大連續使用溫度135℃,最高150℃,用於一般粉塵、烟塵集塵。

▲ POLYESTER(PE) : 最大連續使用溫度135℃,最高150℃,用於一般粉塵、烟塵集塵。

▲ARAMID(NOMEX) : 最大連續使用溫度204℃,最高220℃,用於瀝青拌合廠、石灰粉工廠、陶瓷工廠,有良好的耐磨性和耐酸鹼性。

▲ARAMID(NOMEX) : 最大連續使用溫度204℃,最高220℃,用於瀝青拌合廠、石灰粉工廠、陶瓷工廠,有良好的耐磨性和耐酸鹼性。

▲PPS(RYTON) : 最大連續使用溫度190℃,最高200℃,常用於燃煤鍋爐、窯爐、化學乾燥烟氣除塵、水泥廠、發電廠、化工廠。

▲PPS(RYTON) : 最大連續使用溫度190℃,最高200℃,常用於燃煤鍋爐、窯爐、化學乾燥烟氣除塵、水泥廠、發電廠、化工廠。

▲FIBER GLASS : 耐高溫260-280℃,使用膨體紗除塵效率高,PTFE COATING提升耐化學性,常用於鋼鐵廠、燃煤鍋爐、窯爐、化學乾燥烟氣除塵、水泥廠、發電廠、化工廠、冶煉。

▲FIBER GLASS : 耐高溫260-280℃,使用膨體紗除塵效率高,PTFE COATING提升耐化學性,常用於鋼鐵廠、燃煤鍋爐、窯爐、化學乾燥烟氣除塵、水泥廠、發電廠、化工廠、冶煉。

▲TEFLON(PTFE) : 耐高溫260-280℃,優異的耐酸鹼性能,使用壽命長,良好的抗水解和阻燃性能,常用於鋼鐵廠、燃煤鍋爐、窯爐、化學乾燥烟氣除塵、水泥廠、發電廠、化工廠、冶煉。

▲TEFLON(PTFE) : 耐高溫260-280℃,優異的耐酸鹼性能,使用壽命長,良好的抗水解和阻燃性能,常用於鋼鐵廠、燃煤鍋爐、窯爐、化學乾燥烟氣除塵、水泥廠、發電廠、化工廠、冶煉。

濾袋後處理:

▲ PTFE覆膜: 薄膜由PTFE(聚四氟乙烯)組成,各種超細粉塵除塵皆可使用,光滑表面可減少微塵粘附,可將超細粉塵顆粒分離至濾袋表面,不會滲入濾袋,可達最低排放標準。

▲ PTFE COATING: 提高過濾精度,並且增加濾袋耐酸鹼性能。

▲ 防油潑水: 可避免及減輕因含濕烟塵粘附於濾袋上。

▲ 燒毛壓光處理: 濾材表面經壓光或燒毛後,既提高了清灰效果,同時也提高了濾袋的高精度過濾。

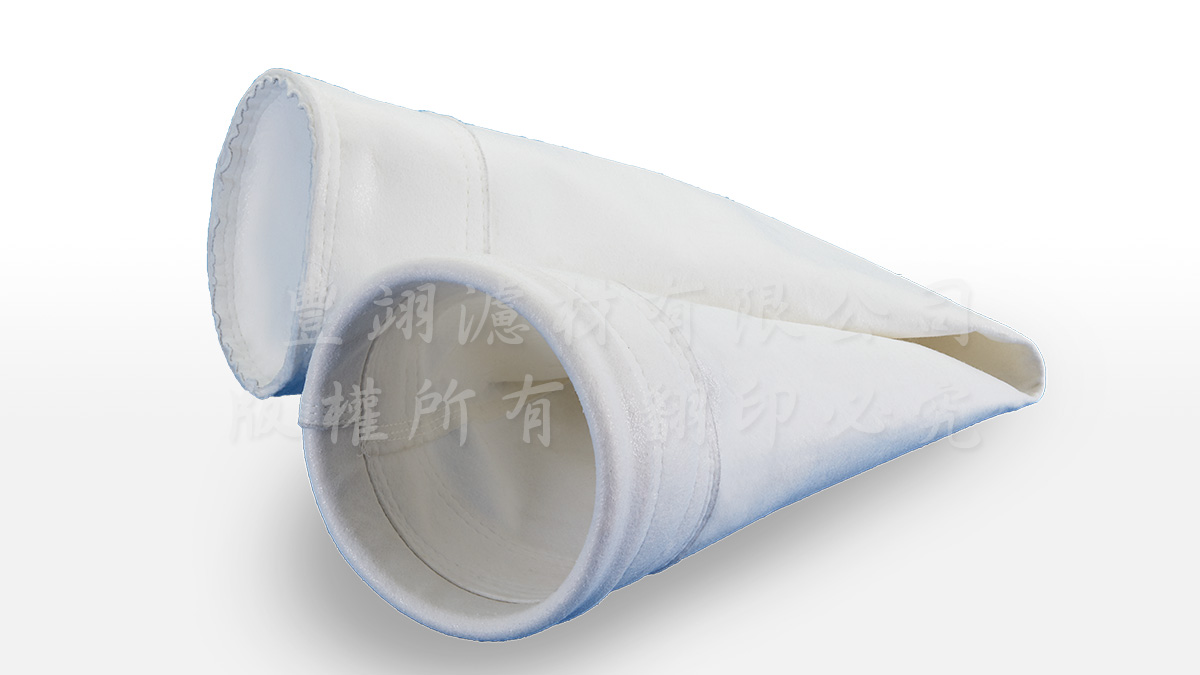

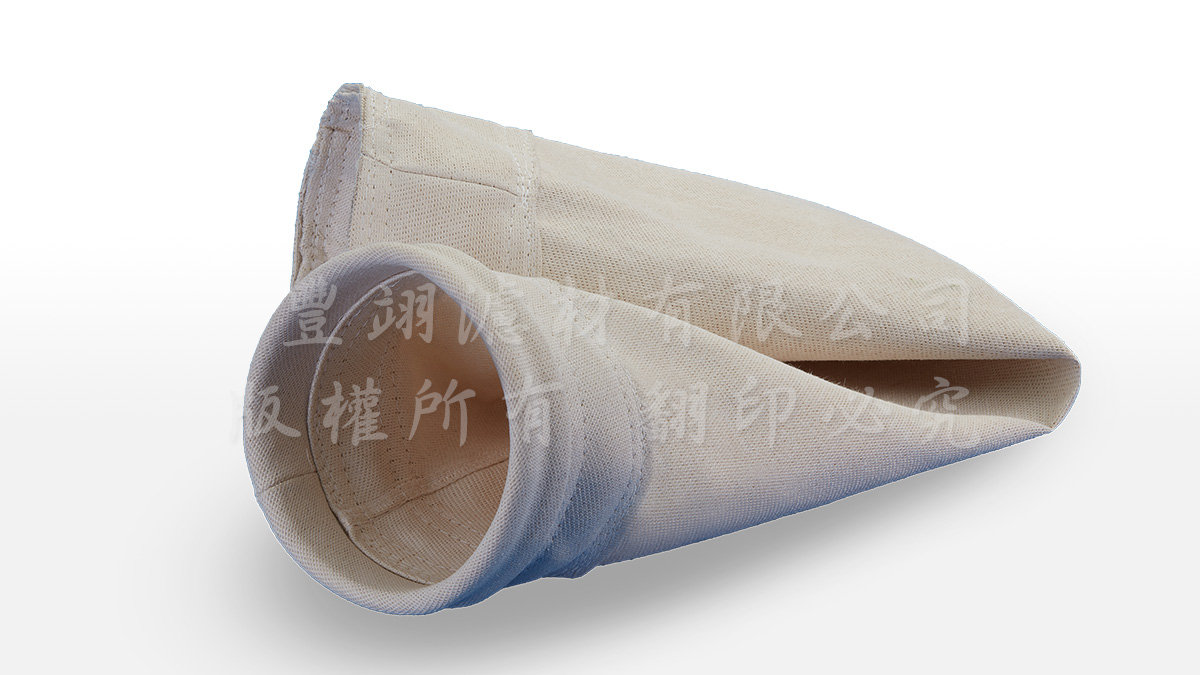

濾袋樣式:

▲ 1. 彈片式濾袋

▲ 2. 法蘭式濾袋

▲ 3. 木工加工機專用濾袋

▲ 4. 平頭式濾袋

▲ 5. 橡膠頭式濾袋

▲ 6. 包鐵圈或包繩式濾袋

▲ 7. 倒吊式濾袋